Commercially Beer and Wine houses have two primary methods of producing "non-alcohol" beer or wine.

1. Filtering. After completing their fermentation process,they will then filter the brew through a fine mesh that only water and alcohol will pass through. They then add back water to their dehydrated pile, reconstituting their brew - alcohol free. If filtered with the finest home filter (1/2 micron), it will be considered fermentation stable removing any yeasts. The amount of alcohol will remain the same - but not increase afetr bottling.

2. Evaporation. Alcohol will evaporate before water. The problem is high heat really spoils the brew. Using Vacuum Distillation allows the alcohol (only) to be evaporated off at a temperature around 70F. This low temperature allow enzymes, yeast, bacteria, and beneficial nutrients to survive with the full taste and richness of the brew - less the alcohol. Its still a very expensive process.

What does a Home-Kombucha Brewer do ?

The Kombucha home brewer must first realize that once beer and wineries finish their ferment there're ready for the store. Most of the fermentable sugars have been depleted. Racking and finning also remove most of the yeast, or the yeast are inactivated by chemicals like potassium or sodium metabisulfite. A known amount of carbonation is anticipated. Their product is stable and contains known amounts of alcohol and pressure from the carbonation.

Kombucha Tea is a Kodak Moment. A incomplete ferment. A large percent of fermentable sugars remain. The yeast and bacteria are still active.. That's how people love their bucha. If one allows their Kombucha to complete its fermentation then it end's up as vinegar. Stop the ferment too soon and it's Southern Sweet Tea.

The bacteria produce the SCOBY in order to prevent the yeast from getting fresh oxygen. Oxygen deprived, the yeast go from Respiration (population building) to Fermentation (alcohol production). The bacteria prefer alcohol to sugar (they also like caffeine: For the bacteria: Sugar, caffeine, alcohol - Life is Good) A good tight SCOBY traps the carbonation (and why there often are holes in the mushrooms or the mushroom seems to float as if trying to escape). Using a thick mushroom that covers the entire area will yield a Tea with more carbonation.

DRY ICE. Adding a small piece of dry ice (available at most grocery stores) will instantly add carbonation.

Know what's in your kombucha.

Aerobic fermenting with T.Delbrueckii for Alcohol Free Kombucha Tea

As we discussed earlier matching different yeast to the gluconbacteria would no doubt result in different flavor profiles. That of course is a different animal. Most (if not all) suitable kombucha yeasts are considered spoilage yeasts to the normal fermenting world. Spoilage may be more associated with such descriptions as “horsey smell” “barnyard odor”, “sour-spoiled taste”.

Consider Torulaspora Delbrueckii, found in many but not all kombucha. This is a aerobic yeasts whose character is associated with German-style wheat beers and banana, clove like aroma. This may not be your favorite character but T. Delbrueckii yeasts does offer critical functionality to produce reliable bottled non-alcohol kombucha tea.

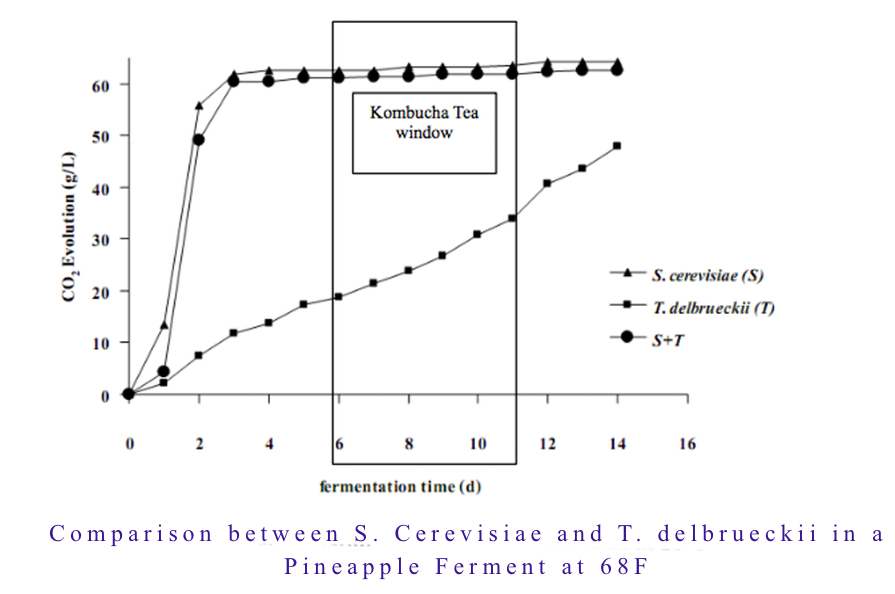

The chart below shows the comparison between Torulaspora delbrueckii and the most popular brewing yeast - Saccharomyces cerevisiae.

This chart graphs the progression of a typical alcohol fermentation.

For kombucha brewing T. Delbrueckii produces significantly less alcohol (5.4%) and does not peak until 14 days. While S. cerevisiae produces 8.4% within 3 days. T. delbrueckii is clearly slow and sluggish. This is what we are looking to produce non alcohol Kombucha Tea. A 14 day to peak time gives time to hyper the gluconbacteria early while providing a larger window for shutting down the ferment (both bacteria and yeasts) via the Cluster Effect. (oxygen deprivation) where pre-determined levels may be reached.

What is not shown is the affect that the co-fermenter gluconobacter - unique bacteria that converts alcohol to the beneficial acetic acid and gluconic acid is actively at work reducing the alcohol to low levels. Gluconbacteria may convert at almost a 1:1 ratio. That is converting all the alcohol to acetic acid given enough time and conditions and one's taste tolerance. Acetic acid is ~ vinegar. A Kombucha Ferment properly fermented exposed to the air results in typically less than 1% alcohol and most often below the 0.05% threshold determined to be non-alcohol. Most of the alcohol related "fears" for the kombucha drinker is when kombucha is bottled. Bottled the gluconbacteria is deprived of oxygen and ceases to convert alcohol to acetic acid. (unless kept refrigerated). That is with almost any other yeasts than T. delbrueckii. T. delbrueckii is a unique aerobic yeasts that only produces alcohol in the presence of oxygen. Just like its bacteria counterpart (gluconobacter) oxygen is needed to ferment. Without oxygen (such as when bottled) fermentation ceases.

Generally yeast produce more alcohol in anaerobic conditions (without oxygen/ when bottled). In a kombucha ferment most of the alcohol is produced in the first few days. The second half of the ferment is where the gluconobacter convert the alcohol to beneficial acids. This occurs only in the presence of oxygen and in temperatures over 72F. In the kombucha ferment this is noticeable by the transition from a sweet tea to a slightly sour, slightly sweet tea and by the appearance of the kombucha SCOBY or mushroom that forms by the gluconobacter.

To keep alcohol to the very minimum, keep the brewing temperature above 72F (74 to 84F is our recommended range) and as sour as you can pleasantly tolerate, and then refrigerate and keep refrigerated until ready to drink. Or be sure to use Torulaspora Delbrueckii as your kombucha yeast.

Another method of keeping your alcohol levels as low as possible is to ferment in OAK BARELS. Oak performs two functions. First the wood absorbs a small amount of alcohol and secondly the wood charcoal absorbs the more toxic methanol compound of alcohol. This leaves a mellow smooth taste with far less bite.

Many kombucha tea folks want low alcohol but they miss the carbonation.

Resorting to a Second Stage Ferment, or simply leaving the bottled kombucha tea at room temperature will increase the carbonation - but also increase the alcohol levels (as the gluconobacter are shut down).

Chemical Additives

The simplest method is by adding a 1/4 teaspoon of calcium carbonate, potassium or magnesium or even baking soda. Any of these beneficial minerals will neutralize a small amount of the acids in kombucha tea. The result is carbonation. This does affect the taste so be careful not to add to much and to add just prior to drinking. KombuchaTea and Coral Calcium helps some 200 degenerative disorders according to research by Dr Barefoot in his book "Calcium Factor".

To neutralize fermentation (prevents more alcohol from developing especially when bottled and left warm) Home Brewers often use Campden Tablets. (sodium metabisulfite). Metabisulfite dissipates into a gas. Trapped it serves as a disinfectant. left open it dissipates into the air usually within 24 hours.

Add one table per gallon just before bottling. This achieves two things: 1. traps oxygen and stops oxidation (flavor changes) and 2. stuns the yeasts. Giving time to chill your brew - or to keep alcohol levels from rising once bottled.

Testing Your Kombucha Tea for sugar, acids, and alcohol levels.

Home testing for sugar levels is simple and inexpensive. The main tools are a Hydrometer or a Refractometer. You test your sugar levels at the start and then again. Subtract and you know how much sugar was used and how much is still there. Typically beer and wine brewers will use the difference in the starting sugar level and the ending sugar level to calculate how much alcohol is in the beer, cider or wine. However with Kombucha's acetobacter busy converting the alcohol to acetic acids , kombucha remains unclear as to how much alcohol versus how much acids. Therefore we use an Acid Test Kit . The Acid Test reveals the total acids in your brew. Add this step - Subtract the Total Acid from the (Starting Sugar Level minus the Ending Sugar level) would equal roughly the alcohol level.

We offer two Kombucha Testing Kits. These also include tools for checking the pH and the temperature. Important tools for consistent quality brewing.

Forced Carbonation will allow you to keep the draught taste and the alcohol as low as possible without adversing effecting the taste and just about a perfect glass of kombucha tea every time. See comparisons on our web site https://www.happyherbalist.com/carbonating-your-brew-how-to-add-carbonation/ Prices range from about $10 for hand-held devices to $50 to $300 for mini-kegs and pressurized Growlers and hundreds to thousands for kegerators.

reference by alcohol content

Vodka - Whiskey 40%+

Wine 8-14%

Cider 5-8%

Beer 3 - 7%

Kombucha Beer > 1%

Fresh squeezed fruit juice less than 1%

Kombucha Tea 1/2 of 1%

Legally anything over 0.5% is considered alcohol by the USFDA

.